Background

The combination of elasticity and rigidity found within mammalian limbs enables dexterous manipulation, agile, and versatile behavior, yet most modern robots are either primarily soft or rigid. Most mammals have ligaments that connect bone to bone, enabling joints to passively redirect forces and softly constrain the range of motion. Hybrid robots, composed of both soft and rigid parts, promote compliance to external forces while maintaining strength and stability provided by rigid robots.

Natural manipulators, such as the human arm, have been shaped by the long-term optimization of evolution. They tend to be extremely versatile, having the dexterity to work with various objects and environments. The hybrid composition of rigid and soft components– including bones, muscles, and connective tissues–yield inherent compliance and flexibility. Biological joints often have passive stability and elasticity that create mechanical feedback that benefits disturbance responses. In addition, recent progress in the mechanical complexity of robots has popularized embedding intelligence within the system. Such robots may inherently dampen motion through elastic components or enable complicated movements emerging from simple actuation, e.g., origami robots.

In contrast, traditional robot arms tend to feature rigid components that are susceptible to large moments propagating throughout the entire robot. This means the robot’s structural integrity can be compromised by a large unpredictable disturbance. Robotic manipulators involving rigid joints have strictly defined degrees of freedom resulting from the mechanical design. These joints typically fit within three categories: prismatic joints (linear movement on an axis), revolute joints (rotational movement around an axis), or a combination of the two.

Rigid robotic joints are often actuated by motors that change their position directly, allowing straightforward kinematic models to calculate the joint's position. Due to their dynamics, traditional feedback control systems, such as a proportional integral derivative (PID) controller, can solve this problem relatively well, with modifications that can adapt to the influences of gravity. One modification to account for nonlinearities involves feed-forward neural networks with PID input features.

While these dynamics are effective within controlled environments, rigid robots pose dangers to both themselves and humans because of their intrinsic inability to deal with external forces. In environments where humans are directly interfacing with robots–such as industrial manufacturing or telepresence -- the robot’s lack of compliance can put workers and civilians at risk of injury. Measures have been taken to increase the safety of these robots, but they are not innately safe. Factors including intrinsic safety, human detection, and control techniques influence the overall safety. The risk that a robot will cause physical harm has also been shown

to moderate people’s willingness to work with the robot. Strategies such as safety fences and human-detection increase safety but limit the human-robot collaboration.

Flexible robots can mitigate these external forces through structural compliance while maintaining morphological similarities with rigid robots. Systems such as soft robots and tensegrity-based robots with elastic components are inherently compliant. Biologically inspired approaches tend to exemplify this behavior. The motion of legged tensegrity structures has been validated by biological simulations while simplifying the underlying bone-ligament architecture. From a bio-mimicry perspective, a human finger has been functionally recreated through oneshot three-dimensional (3D) printing techniques employing both rigid and elastic components. Soft robots can provide safe human interaction, resulting in safer environments. Soft cable driven exo-suits can be compliant while avoiding obstruction to the user’s range of motion. Intelligent design approaches have even resulted in programmable tensegrities. However, due to the non-linearities within the elastic components, these compliant robots tend to require complex models in order to be controlled properly.

Soft robotics made from elastic components increase compliance while often sacrificing stability and precision. An accurate model of the system would enable the use of modern control techniques which can provide optimal solutions. Optimal control finds the proper control values which optimize an objective function based on the system model. A Linear-Quadratic Regulator (LQR) solves the problem of minimizing a quadratic cost matrix (encoding weights of errors, energy use, etc.) over a specified time horizon, however it is expensive and demands accurate models. Model predictive control optimizes a finite time-horizon window that is repeatedly solved at each new time-step, reducing computational cost while enabling anticipation of future events. To create the model, a common method involves system identification, which can estimate the dynamics based on measurements.

However, noise in the design process can breed inconsistencies in production, and the non-linear nature of flexible robots further complicates modeling. This emphasizes the need for control methods that can learn from data. One potential solution for controlling this variation in robots involves having precisely adjusted models for each physical instance. But these approaches are cumbersome due to the requirement of constructing precise models. Thus, there is a need for a system and method of controlling soft-rigid hybrid robotic joints that overcome the deficiencies of the conventional control methodologies.

Technology Description

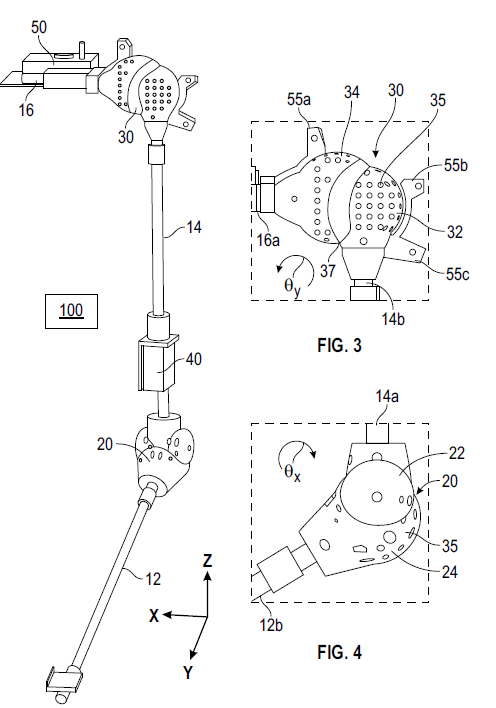

Robotic Joints/Robotic Arms: a soft-rigid hybrid robotic joint with through-holes that increase flexibility and compliance in the "ligament" sections of the joints. The joints can be designed by 3-D printing with a molding process that supports interfacing between soft and rigid compnents. Three types of joints are described: perforated, semi-perforated, and solid that are differenitated based on the number of through-holes in the ligament.

Designing Robotic Joints through machine learning: The technology also involves variable kinetic parameters that are controllable through machine learned methods that provide a novel approach to designing and constructing a hybrid joint through parametric design choices that adjust dynamic properties of the system. Dealing with the inherent modularity and variability necessitates a model-free controller that adjusts to new contexts in a relatively short time.

Reinforcement learning (RL) solves the problems of conventional control methods described in the background above through a data driven approach to solve the optimal control problem. Deep reinforcement learning (DRL) extends this framework by using neural networks as parameter estimators. In DRL, algorithms solve for an optimal policy that will compute the control value (or action) from the current state of the system. This is termed a “model-free” control method, which are control methods that do not explicitly model the dynamics of the system.

DRL solves control problems through gathering data, surpassing human skill in the domain of games, teaching legged robots to walk, and much more. However, neural algorithms are data intensive and gathering data on robots can be incredibly costly in machine-hours, making sample efficiency important. Transfer learning provides a method for reducing training time by using prior knowledge. Whether through examples of expert trajectories or an agent trained in simulation, transfer learning involves an agent leveraging training experience from some domain A to perform better on a new task in a similar domain B. In the case of robotics, simulations provide a route to shortening real world training times through pre-trained models that can be fine-tuned on the physical robot.

The joint design begins with a simplistic 3D printing approach enabling easy customization with a molding process that supports interfacing between soft and rigid parts. Customization includes modifying the perforation of the rigid components, resulting in three types of joints (i.e., perforated, semi-perforated, and solid), each with distinct ligament meshes. The joints are characterized through spring and damper experiments to provide insight in how the modification changes the dynamics. These experiments expose significant nonlinearities in the system and identify how design parameters can modulate the spring-damper terms, leading to future work of programmable dynamics. The parameters found inform a simulation, e.g., MuJoCo, enabling the use of transfer learning, e.g., transferring machine learned knowledge or an algorithm from a simulation to a physical/real world.

Model-Free Control Methodologies: Model-free control methodologies include a proportional-integral-derivative (PID) controller and a Soft Actor-Critic (SAC) algorithm. Three tasks were designed to evaluate the accuracy of each controller. The tasks were termed: 1) increasing steps, 2) decreasing steps, and 3) sinewave. The SAC policy yields greater precision through a wider range than the tuned PID controller, and robustly solves the presented tasks by generalizing through the disclosed joint designs. This results in the ability to design soft-rigid robotic joints with parameterizable stiffness and damping. Model-free DRL is used to compensate for variability and non-linearities.

Robotic Arm Diagram

Applications

Soft and semi-soft robotics systems

Human-robot interactions (human-cyborg relations)

Robot design by machine learning/AI

Control methodologies requring minimal user input

Ball and socket joint and/or elbow joint

Advantages

Soft/rigid hybrid robotic joint controlled by machine learned methods.

Uses Reinforcement learning

3-D printed design

Intellectual Property Information

| United States Of America |

Published Application |

20220281123 |

09/08/2022 |

2021-592 |

| |

|

Additional Patents Pending

Related Materials